Simulator is one of the features TMMonitor provides to our customers. Simulator is designed to make inspection planning easy and more automatic, it is possible to simulate one unit at the time even up to simulating whole fleet at the same time.

Simulator calculates automatically the best part rotation between multiple units based on units operational values and lifetime of installed/stock components.

Only thing you need to do is select units simulated, input starting values for the units/simulation and press start.

Simulator calculates required inspections to selected simulation period for all the units. It is not a problem for simulator if the units are sharing parts between each other as simulator rotates parts automatically between compatible units to find the best parts rotation, this is why simulator is essential tool if you want to make accurate inspection planning for multiple turbines.

What does simulator provide?

- Timing of inspections

- Parts in/out lists for inspections

- Required consumables lists for inspections (installation hardware)

- List of new parts required to purchase

- Timing when new parts are required to be purchased

- Timing of part repairs

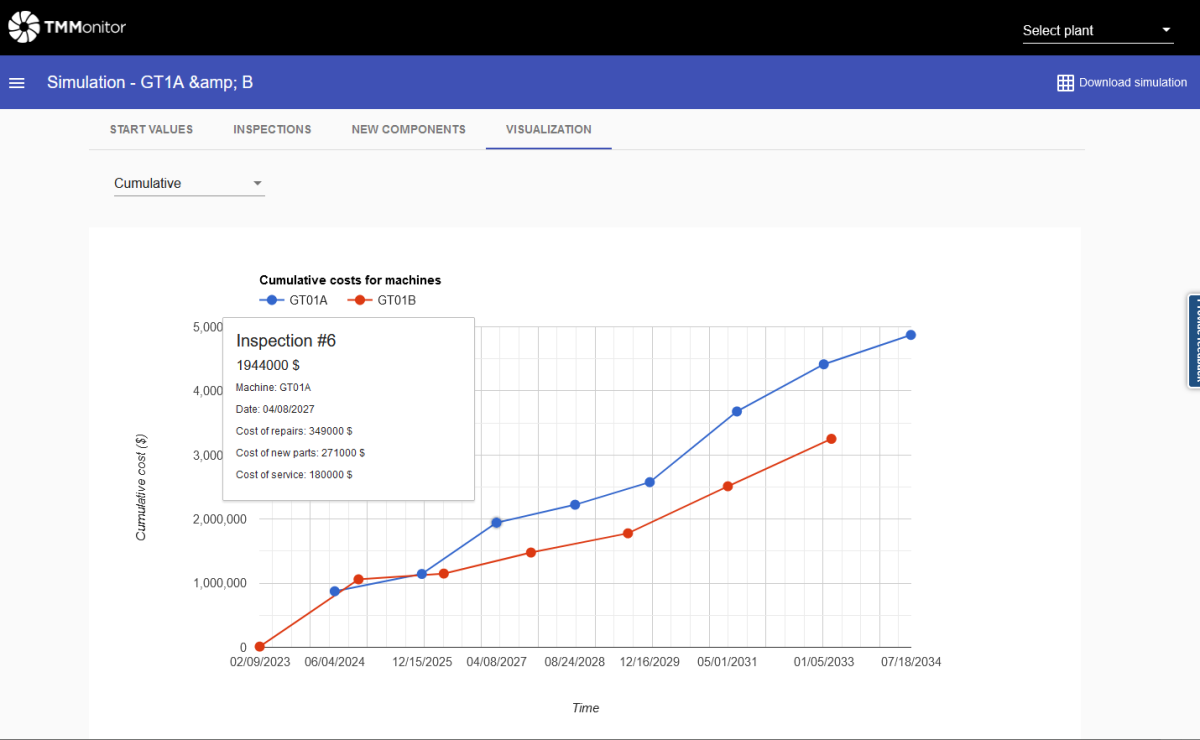

- Costs of part repairs

- Costs of new parts

- Costs of service work for different inspections

- Visual graphs of inspection budgets and total costs

- Ability to compare different simulations between each other to find the most efficient maintenance plan.

Additionally it is possible to download full simulation data to different softwares such as excel or Power BI.

Save money and time with more efficient inspection planning using TMMonitor simulator tool!