Highlights of GTUsers GTUsers Webinar

SGT800 Webinar was held in November 2021 and served as a preparation for the May 2022 conference. Participation to the event exceeded expectations. Planning of the events were started well in advanve by Group Steering committee and GTUsers standardized platform was used for all events making it very straightforward for end users to join in the webinars.

More information of the held Webinars and coming meetings can be found at: GTUsers.com

Users Session

The first Session was dedicated to end users only. The end user Webinar consisted of number of case studies on noteworthy events and lessons learned. Also, Users Q&A session was added in the end of the User Webinar where Users questions listed as part of the pre-conference questionnaire was discussed in detail.

|

Key lessons discussed:

Extensive discussion and more detailed presentations continue in the May 2022 conference. If you own and operate a SGT800 gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register. |

|

General Electric

|

GE Gas Power Session Summary on GE Gas Power Cross Fleet Solutions for SGT-800*

Need additional information? LINK to Contact GE sales or support. |

|

3rd Party Service Providers

|

|

Arnold Group, The most advanced Turbine Insulation combined with high performance heating System. ARNOLD has been comparing traditional Insulation provided by the OEMs and compared it in terms of fitness, tightness, efficiency and maintainability with the ARNOLD Insulation system. The focus of the presentation was on explaining the advantages of a Single Layer Insulation system in terms of operation and maintenance as well as durability and cost efficiency. Most of the Units in the field are still using the original standard multilayer insulation with poor performance due to many removal and reinstalls which are causing ongoing degradation and related repair effort and cost. The Solution ARNOLD provides will cut cost during maintenance and increase the performance during operation. |

|

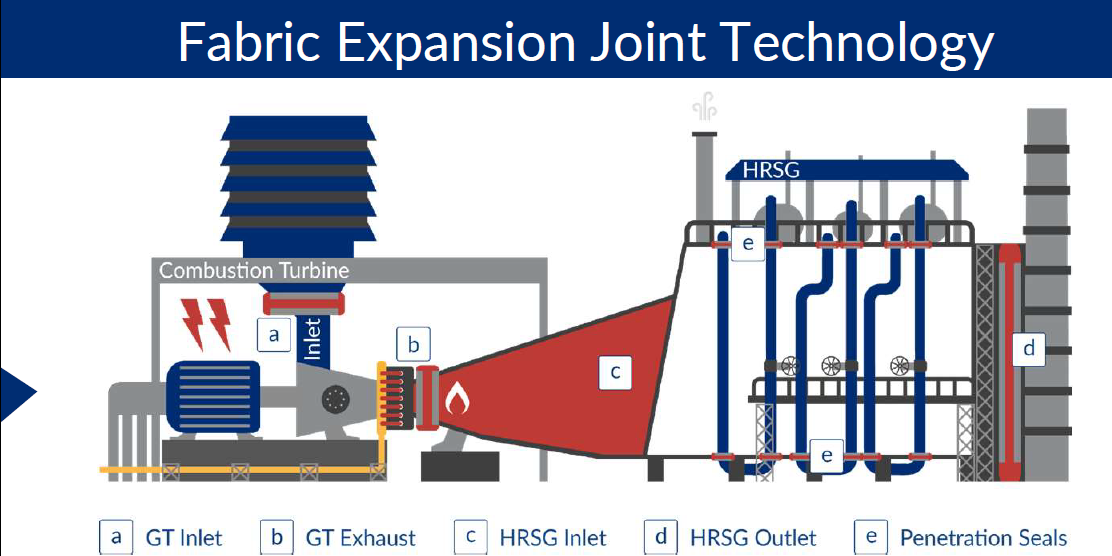

DEKOMTE manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for. DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte explained technologies, selection and criterias for proper expansion joint selection and maintenance:

|

|

|

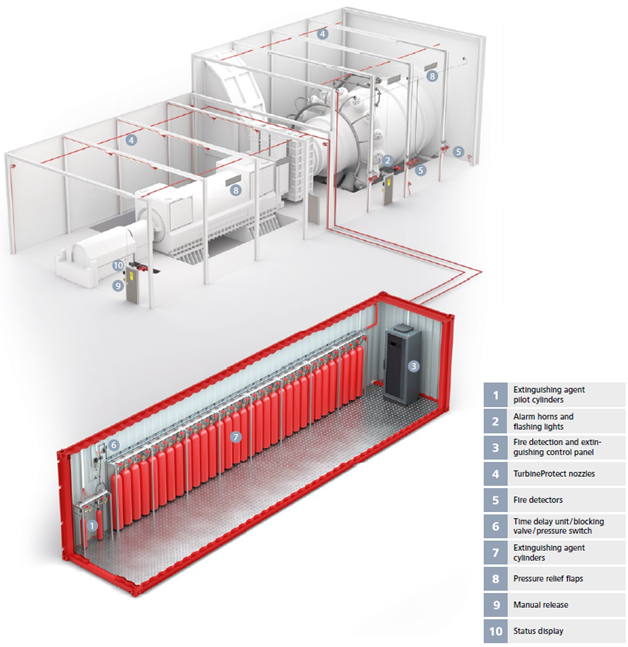

Minimax Fire Solutions International GmbH - Office Bremen, Competence Center Power, Oil & Gas is specialized in firefighting systems for gas and steam turbines, compressors, generators, motors and engines. They have successfully executed orders in the Oil & Gas market and also provide fire and gas detection systems according to SIL 1, 2 & 3 (Safety Integrity Level). Minimax fire detection and protection systems are installed in more than 500 Siemens Gas Turbines worldwide. Majority of these turbines are of type SGT800 and its predecessor model GTX100. Since these turbines are already in operation for years, Minimax talked about some very important aspects related to their systems as: 1. Service:

2. Modernization/Upgrades:

FMZ 4100 HAS TO BE EXCHANGED AS SOON AS POSSIBLE!!! 3. Spare Parts:

All the relevant documentation, customer information letters and presentation are available for GTUsers end users to download from the Link to Minimax page on the GTUsers website.

|