TMMonitor is a centralized system that contains all information on the maintenance inspections and parts as well as related documentation and service bulletins accessible by multiple users.

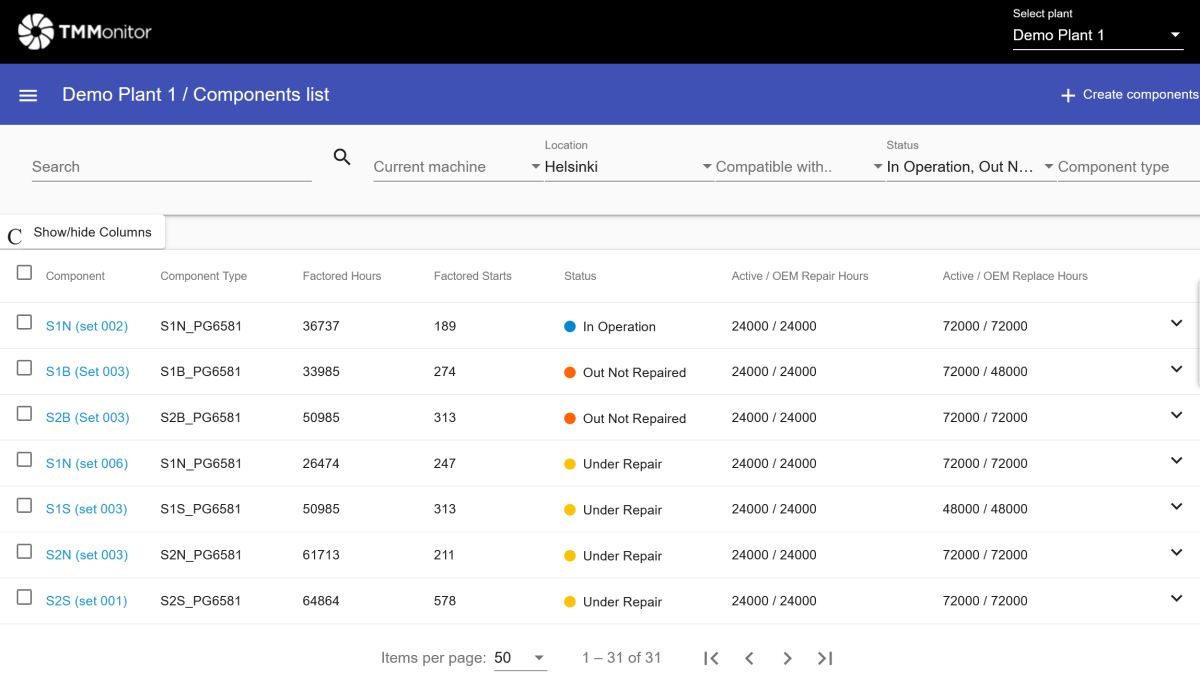

TMMonitor provides an efficient method for overall management of maintenance inspections that serves all the parties in the organization when it comes to managing turbine parts and inspections and planning future maintenance measures.

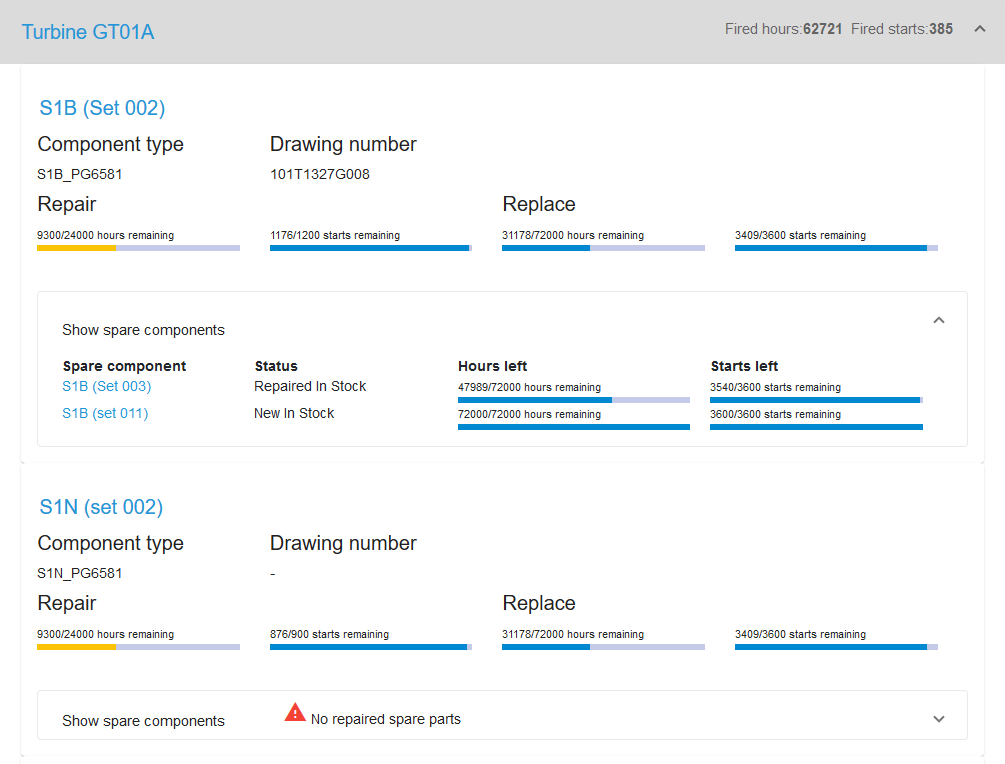

- Planning and budgeting of future maintenance needs can be made in a cost-efficient way. Through TMMonitor you know the complete, exact history of the turbine to establish an accurate future estimate.

- Parts rotation can be optimized and new parts procured on time.

- Parts cost history and remaining value is easily available.

- Management of history information and maintenance planning is straightforward and saves time and money.

- As TMMonitor is operated through a web browser it does not require any investment in own data storages or special programs. You can use it in your PC/laptop/tablet/smartphone.

- You can have different user levels from read only to full access depending on user requirements. User access levels can be controlled by the administrator of the end user organization.

- TMMonitor makes your centralized maintenance information easily accessible in real time even on your smartphone.

A centralized system that contains information on maintenance inspections and parts as well as related documentation and service bulletins facilitates the planning of best practices for the safe use of turbines.

TMMonitor provides an easy and fast way to know what parts are on stock and what their useful life or condition is and which gas turbine they are applicable to. All information on maintenance inspections and parts available is easily and fast available to those who need it.

Access the data immediately and by multiple persons during a forced outage. Get immediate update about latest inspection, installed parts and their full history.

- Reserve parts in advance for an inspection

- Avoid installation of a wrong part

- Confirm part status prior usage.

- Rotation and efficient usage of parts can be better optimized avoiding unnecessary procurement of new parts.

- A centralized system that contains information on maintenance inspections and parts as well as related documentation and service bulletins facilitates the planning of best practices for the safe use of turbines.

- Information on maintenance inspections and parts available is easily and fast available to those who need it.

We value high availability, security and safety. Owner’s data is backed up regularly. You never lose your data.