Long term service agreements (LTSA) are becoming key factors in determining the success for Power Producers. This is due to the constant challenges of the Power Market, as well as the fact that maintenance strategies are in need of asset management and optimization much more than preservation and protection.

The main issue in entering into an LTSA is defining its specifications with care. When and if original equipment manufacturers (OEMs) are just invited to bid for maintenance services, they are more than likely to offer LTSAs that are the most lucrative for them. They also tend to prefer commercial stipulations and technical terms that benefit them, not the gas turbine power plant equipment owners.

In fact, the LTSAs that the OEMs offer often conflict with the actual needs of the equipment owners. Comparing different offers is challenging because the scopes of the offers vary so much. Furthermore, contractual negotiations are very hard because so many terms and stipulations have to be negotiated and re-negotiated several times over.

The implementation of a successful LTSA requires careful preparation and detailed invitation to bid (ITB) specifications. Without careful planning and specifying what is actually needed, you may well end up with proposals which are not in line with your expectations. Different proposals might not even be comparable. This not only makes evaluating different proposals difficult but also considerably prolongs the period of contracting the services.

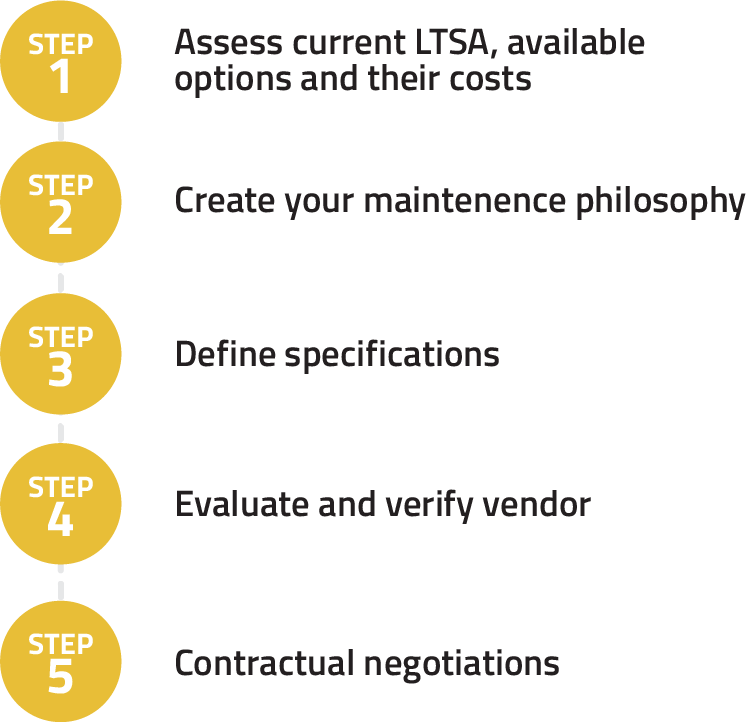

The 5 steps to a successful LTSA is Gasre’s bespoken service for each customer to secure an effective and appropriate contract.

Step 1: Site assessment

Everything starts with a client meeting where both site and client preferences are defined. The meeting should include:

- site configuration (turbine model, fuel, auxiliaries, inlet system, etc.)

- operation values (cyclic/continuous, FFH/starts, part/base/peak load, vibrations, performance, etc.)

- history (inspections/reports, outages, specific problems, etc.)

- client capabilities, own crew

- site facilities (cranes, laydown area, crew facilites)

- current LTSA structure and pros/cons

- market situation (available vendors)

- costs of maintenance options

While many Owners are entering into an LTSA for the first time, others are faced with the challenges of implementing LTSAs that were entered into when the equipment was first ordered, possibly many years ago. Still other Owners are faced with analyzing LTSAs that they themselves have not negotiated but inherited as part of an asset acquisition.

If there is an LTSA already in place, a cost review can be made which can then be compared to market analysis. This provides insight into the cost effectiveness of the current LTSA. It is also invaluable in determining whether the existing LTSA should be renegotiated or not.

The other steps are:

Step 2: Maintenance philosophy

Step 3: Specification definitions

Step 4: Evaluation and vendor verification

Step 5: Vendor selection & contractual negotiations

We have consulted numerous gas turbine power plant Owners on their LTSAs for over two decades all over the world. In doing so we have helped them to reach just the right long term service agreements for their needs.

In the process we have also saved them a considerable amount of money.

Are you on top of your LTSA? If not, contact us for giving you a consult. You can also check all the steps and download our white paper ‘5 Steps to a Successful Long Term Service Agreement: How to Avoid Contractual Pitfalls.’

Download