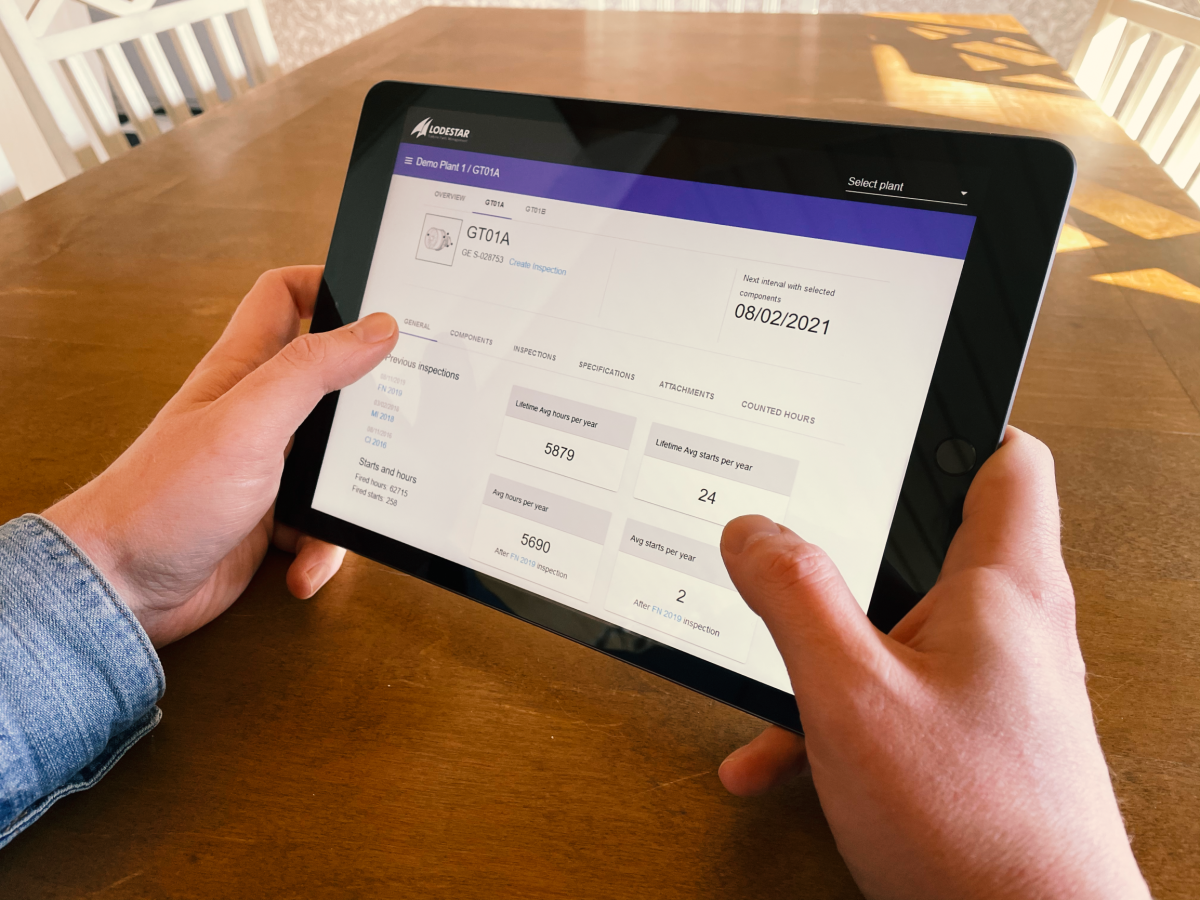

TMMonitor® makes updating of your maintenance data and planning of future inspections easy and straightforward. Data entered is available easily and fast to those who need it. And most importantly, data is never lost.

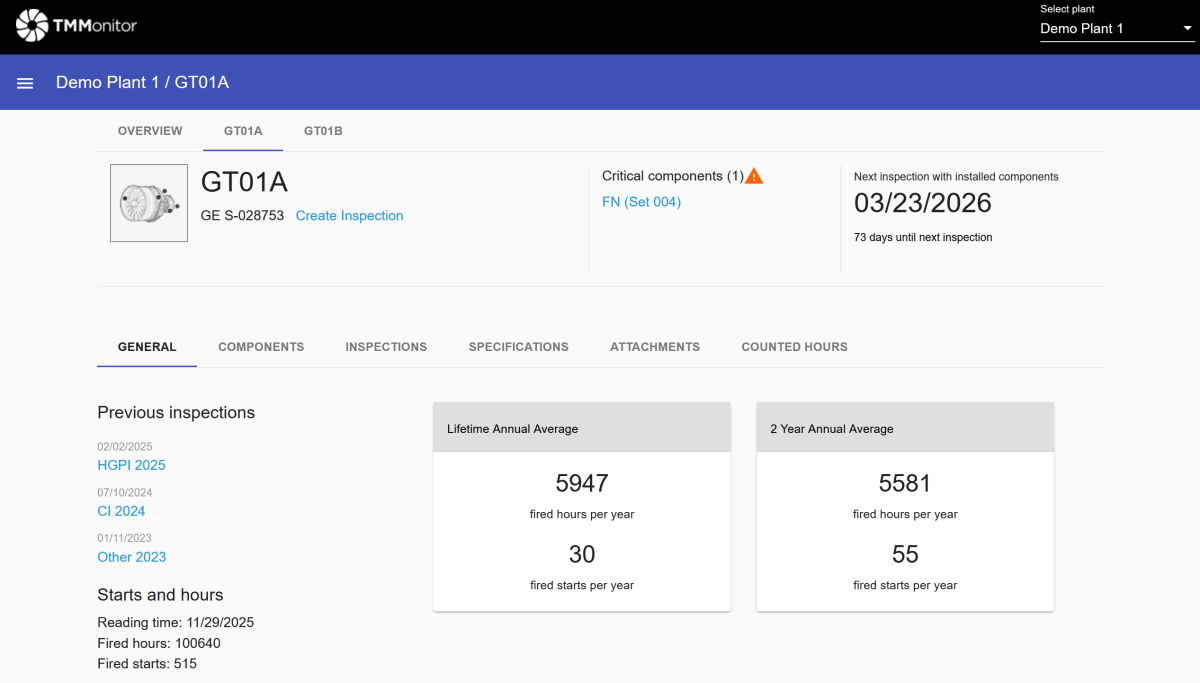

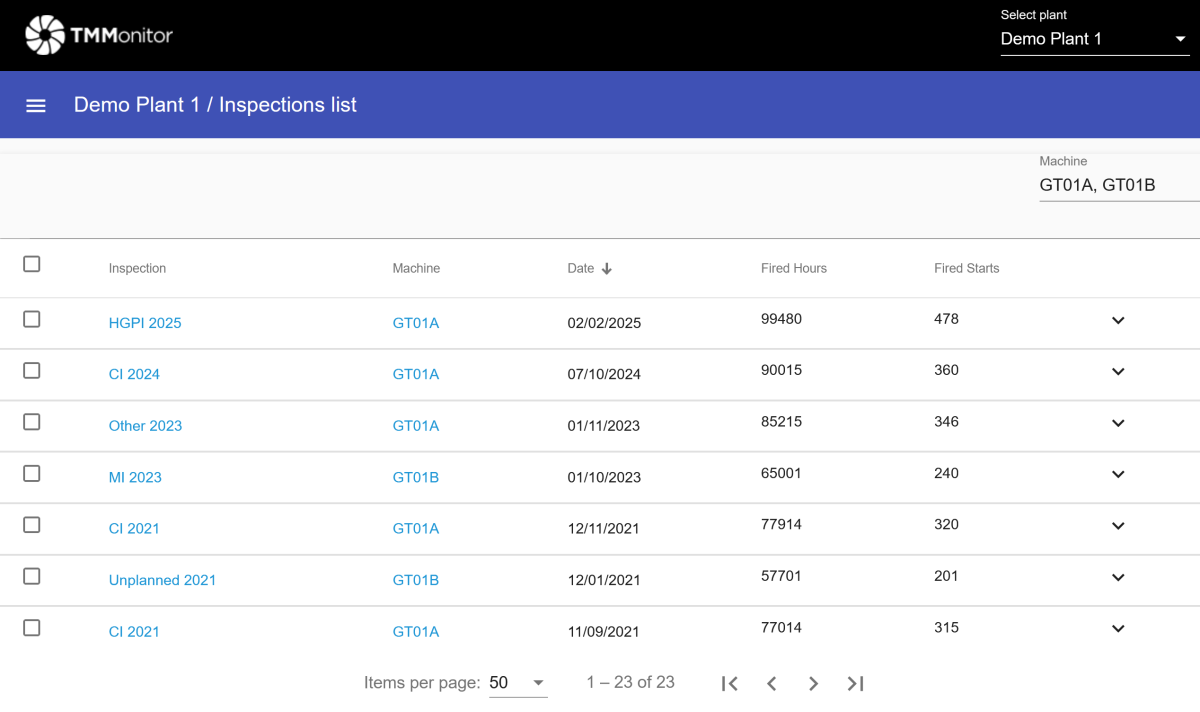

Find all inspections made for each turbine including complete data with uploaded inspection reports and made service bulletins.

- Inspection date and duration

- Operating hours/starts and corresponding equal operating hours/starts at the time of inspection

- Parts in/out

- Inspection reports, photos and notes

- Inspection costs

- Applied service bulletins

- Pre/post inspection performance

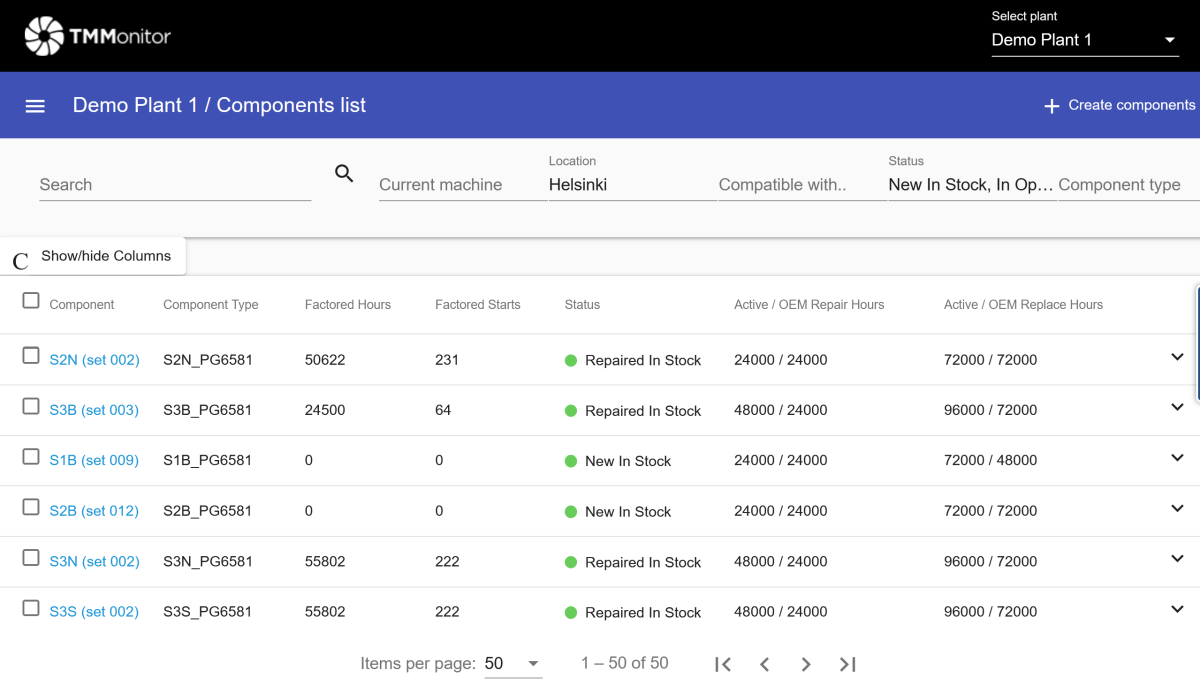

Monitor the status, history and remaining lifetime of parts through parts history and usage calculator.

- What parts are installed in different gas turbines

- Current status –in operation, repaired on stock etc.

- Which turbines each part is applicable to

- Equivalent hours and starts and remaining lifetime prior repair and prior end of lifetime

- Full operating and repair history including repair reports

- Check how operating hours/starts affect the remaining lifetime and timing of next inspection

- Future usage by the simulator

- Tracking down to single items (blades)

Operational data can be uploaded manually using excel template or automatically from Client dedicated location.

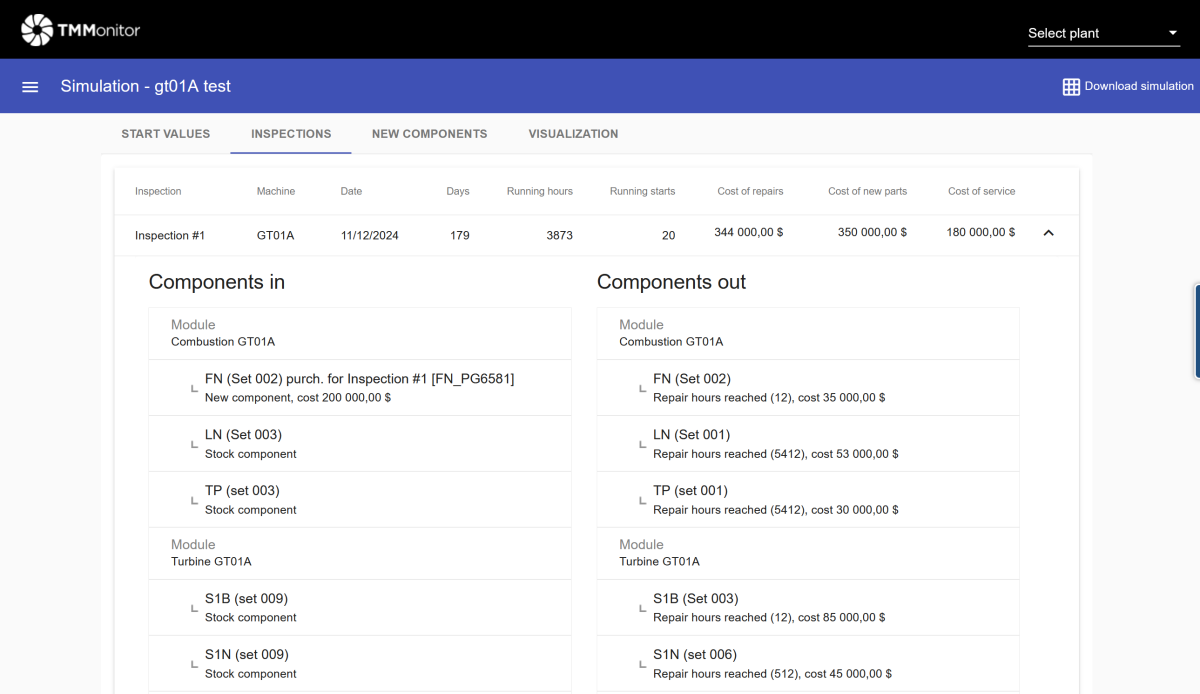

Simulator provides you a tool for future planning.

- A quick tool to view how different annual operating hours/starts affect expected timing of scheduled maintenance events

- Make inspection plans based on different operating scenarios

- Establish simulated inspections, reserve parts and make parts procurement plan for future inspections. Get an inspection budget based on your inspection plans.

With TMMonitor you can monitor costs and make budget planning for future inspections.

- Cost of maintenance €/MWh, $/MWh

- Total costs of parts and inspections

- Remaining value of parts

- Budget for future inspections

Information on maintenance inspections and parts available is easily and fast available to those who need it. Updating of the new inspections and parts database is easy and can be done where internet is available.

- Make future inspection plans using simulator in the office with your team or through internet with GASRE

- Make inspection notes and take photos to TMMonitor beside the turbine during the course of a maintenance inspection

- Review with field engineers your inspection plans and service bulletins to be applied.

- Print part history for repair Vendors or allow access to TMMonitor for direct update of part repairs.

- Check content of part boxes at the warehouse through software QR codes.

We value high availability, security and safety. Owner’s data is backed up regularly. You never lose your data.

TMMonitor provides an efficient method for overall management of maintenance inspections that serves all the parties in the organization when it comes to managing turbine parts and inspections and planning future maintenance measures.

- Planning and budgeting of future maintenance needs can be made in a cost-efficient way. Through TMMonitor you know the complete, exact history of the turbine to establish an accurate future estimate.

- Parts rotation can be optimized and new parts procured on time.

- Parts cost history and remaining value is easily available.

- Management of history information and maintenance planning is straightforward and saves time and money.

Information on maintenance inspections and parts available is easily and fast available to those who need it. Parts in operation, their useful remaining life and repair reports are immediately accessible in case of a forced outage situation. This gives time savings and shortens the outage.