Highlights of GTUsers organised Webinars

Due to Covid restrictions, famous in-person End User Conferences were rescheduled to 2021 and instead of in-person meetings in 2020, GTUsers organised end user Webinars.

SGT800, V94.3A (SGT5-4000F), V94.2 (SGT5-2000E) and F9FA/FB Webinars were held in late fall 2020. Participation to the events exceeded expectations. Planning of the events were started well in advanve by Group Steering committees and GTUsers standardized platform was used for all events making it very straightforward for end users to join in the webinars.

More information of the held Webinars and coming meetings can be found at: GTUsers.com

Famous User Webinar

The first Webinar was dedicated to end users only. The end user Webinar consisted of number of case studies on noteworthy events and lessons learned. Also, Users Q&A session was added in the end of the User Webinar where Users questions listed as part of the pre-conference questionnaire was discussed in detail.

|

SGT800 Users Webinar on 22nd of September 2020 A lot was discussed on main operational and maintenance cases and intervals. Key lessons learner:

If you own and operate a SGT800 gas turbine and are not part of GTUsers SGT800 Users Group, pls visit now GTUsers.com and register. |

|

|

F6FA Webinar on 20th-21st of October 2020 6FA End User Webinar covered the following main topics:

Compressor performance under off design conditions like dirty compressor, part load operation, grid frequency variations was discussed extensively. Also flexibility; startup times, alternative fuels like hydrogen dilution was getting major interest within the end users. GE 6FA has excellent capabilities for alternative fuel applications and for flexible operation. Additionally User questions to various 6FA topics were reviewed and duscussed in a Q&A Session. |

|

V94.3A (SGT5-4000F and AE94.3A) on 28th-29th of October 2020 V94.3A Webinar covered many topics raised by end users with presentations about 5 main topics.

|

|

|

F9FA/FB Webinar on 3rd-4th of November 2020 F9FA/FB Webinar was the largest of all webinars. A lot was discussed around the FB unit and latest end user experience.

And of course flexibility improvements like fast startups, alternative fuels (hydrogen), longer maintenance intervals.

|

|

V94.2 (SGT5-2000E and AE94.2) on 10th-11th of November 2020 V94.2 Webinar was very interactive again. V94.2 as a mature gas turbine has become a very succesful turbine type again due to its flexibility and ultra fast startup features.

|

|

Vendor Presentations

|

MD&A offers services and repairs for 6FA and 9FA turbines

|

|

|

Arnold made a very interactive presentation and answered to the following questions.

Arnold services include:

|

|

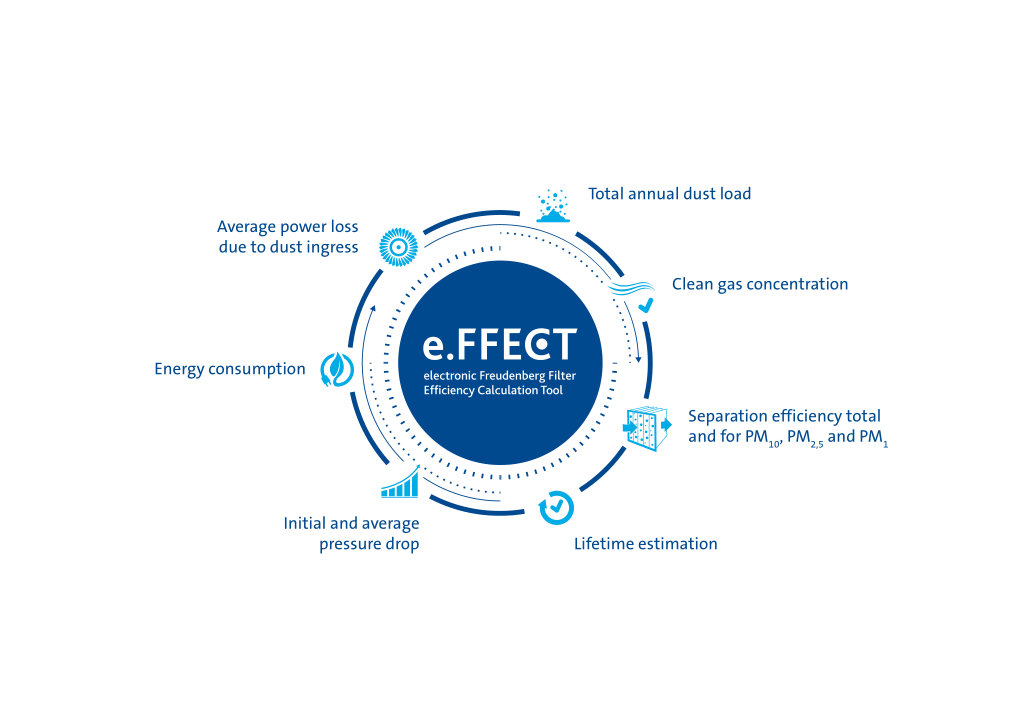

E.FFECT BOOSTS PERFORMANCE FOR GASTURBINES For plant operators, intake air filtration offers valuable potential for optimization. To make this potential visible, Freudenberg has developed a software solution that allows you to compare the performance and efficiency of appropriate air filter systems: The electronic Freudenberg Filter Efficiency Calculation Tool, or e.EFFECT for short. The simulation tool maps the reality of your individual plant in a digital model and determines a range of suitable filtration systems based on specific parameters and relevant variables. The advantages of these systems are compared in a transparent manner and make it easier to decide on the best solution. GTUsers members can access the program directly at Freudenberg at GTUsers |

|

|

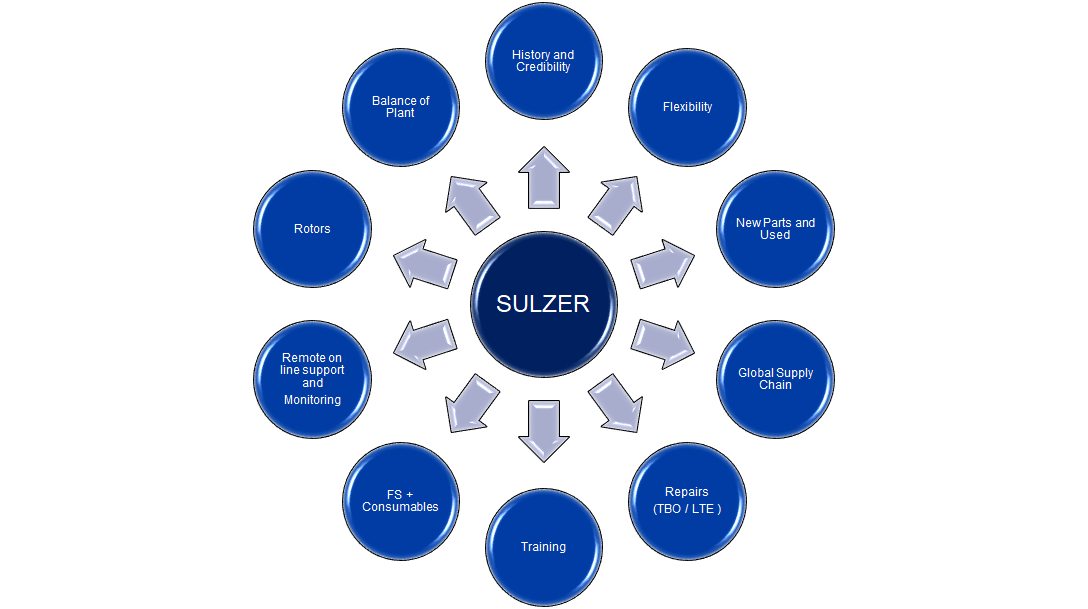

Sulzer can now provide an experienced and tested alternative solution to the 6FA.01 and 03 Users with parts, repairs, field service and rotor overhauls to which have all been exercised and proven in supporting current LTSA and transactional customers.

|

|

|

|

GTC KEEPS YOUR:

GTC presentation was handling important topics:

|

|

DEKOMTE de Temple offer innovative and quality expansion joint solutions to bring reliability of operation in combined cycle power plants, whilst also creating better technologies that benefit both the customer and the environment. |

|

|

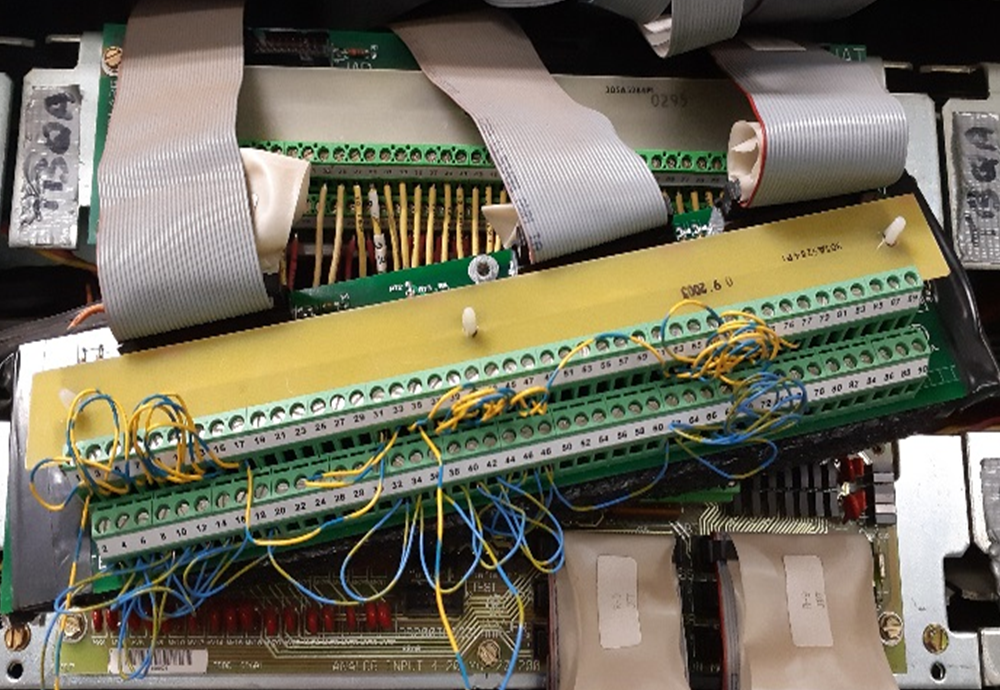

Emerson Emerson’s Laurence O’Toole presented a case history on an upgrade of Teleperm XP (TXP) control systems on three V94.2 gas turbines to a modern Ovation control system. The presentation detailed the equipment removed alongside the replacement solution. O’Toole also explained the engineering and commissioning aspects of the project, noting how the replacement system was designed to match with the existing Siemens system so as to ensure an easy transition for operation and maintenance personnel post-upgrade. O’Toole explained some of the benefits of the upgrade, including rationalization of spare parts, improved troubleshooting and easier maintenance, and resolution of some outstanding control issues on the units. For more information, contact Laurence.otoole@emerson.com |

|

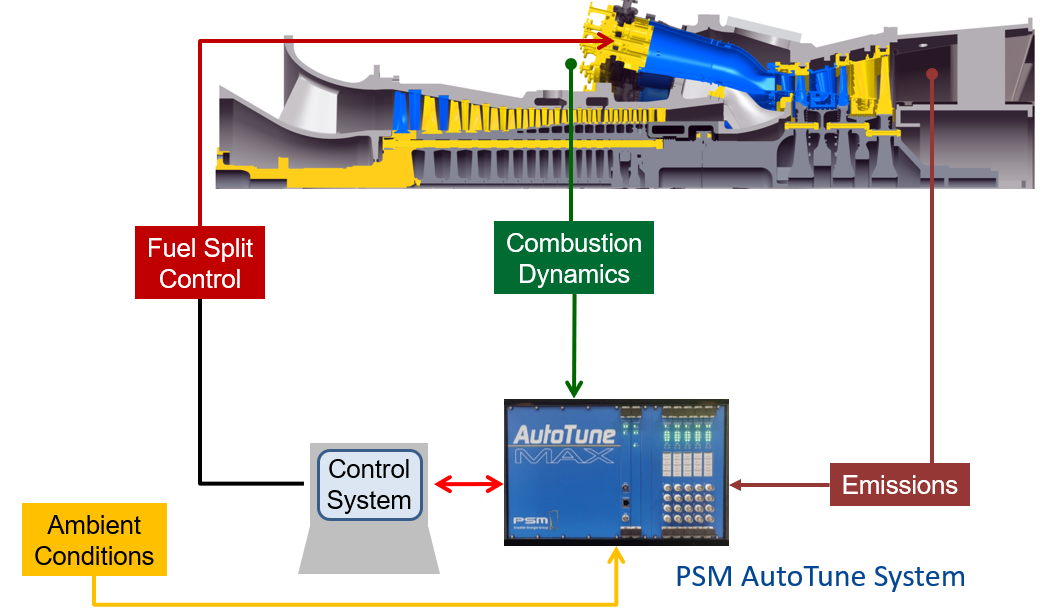

PSM Ansaldo PSM Ansaldo provides full range of services for 6FA and 9FA gas turbine end users:

|

|