Highlights of GTUsers Webinar

GT26 Webinar was held in March 2022 and served as a preparation for the November 2022 conference. During restricted COVID time, the event still represents an excellent opportunity to meet other operators from all over the world, openly discuss and share feedback and updates from the fleet.

Participation to the event exceeded expectations. Planning of the events were started well in advanve by Group Steering committee and GTUsers standardized platform was used for all events making it very straightforward for end users to join in the webinars.

More information of the held Webinars and coming meetings can be found at: GTUsers.com

Users Session

The first Session was dedicated to end users only. The end user Webinar consisted of number of case studies on noteworthy events and lessons learned. Also, Users Q&A session was added in the end of the User Webinar where Users questions listed as part of the pre-conference questionnaire was discussed in detail.

|

The following key topics was presen ted at the Webinar. Due to limited time majority of topics and questions will be covered in the coming End User Conference in November 2022. Generator vapor phase connection failure and preventive actions to avoid an incident.

New OTC Valves Issues and a failure in the MCW rubber liner pipework.

If you own and operate a GT26 or GT24 gas turbine and are not part of GTUsers Users Group, please visit now GTUsers.com and register. |

|

Ansaldo Energia and GE Power

|

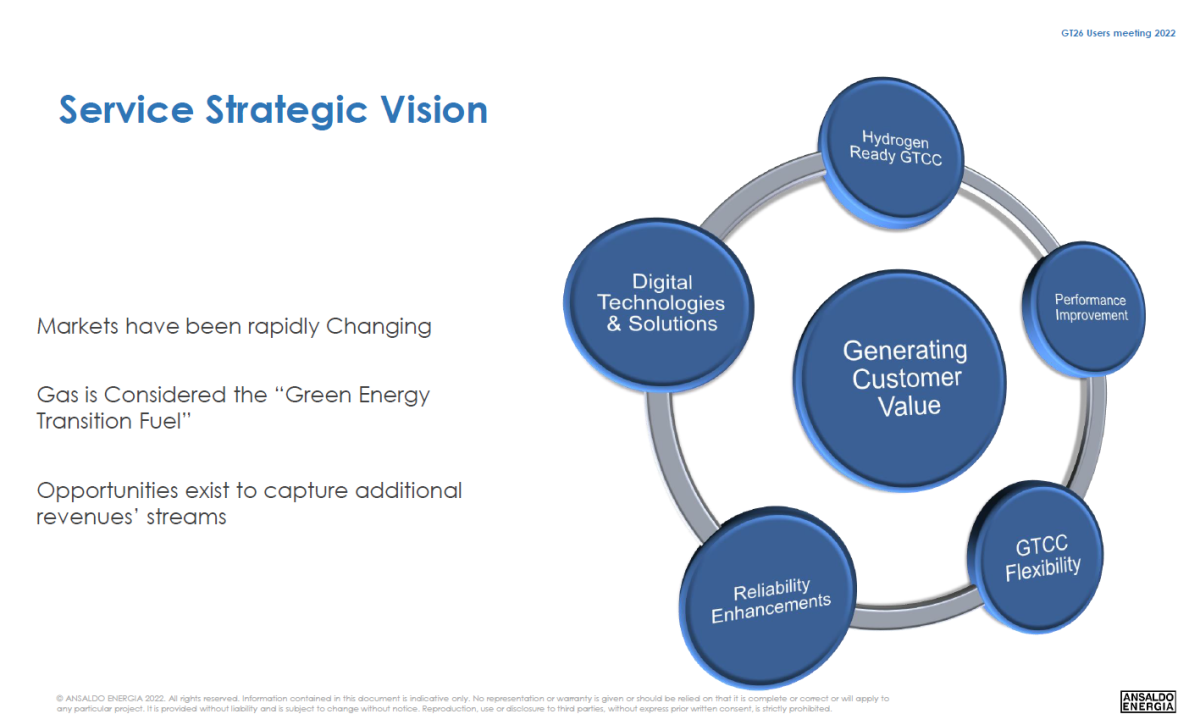

Ansaldo Energia Session Ansaldo Energia was present at the Users Webinar dedicated to the GT26. This GT technology offers a most proven platform in the F class market, suitable for both high performance and flexible combined cycle applications.

Technical session obviously raised a lively discussion, and the chat was also used extensively. In the end Ansaldo provided an overview of the market and product trends during the upcoming energy transition period introducing Ansaldo Green Tech, to support plants competitiveness in challenging markets, especially focus on hydrogen and energy storage solutions. This topic will be discussed more in the coming Users Conference in November 2022. |

|

|

GE Gas Power Session GE Gas and Power session was very informative with active participation and engagement. The March ´22 GE session highlighted another important milestone for the GT26 HE that successfully reached the 1st A-Inspection on our fleet leader unit. It then provided a detailed GT fleet status update with focus on key ongoing RCAs and expanded on control systems obsolescence, Mark VIe migration path and Controls Service Offering (CSO) which is a combination of services to help manage the life-cycle needs of control systems. Moving beyond the GT, the focus shifted on how we go about assessing overall plant capabilities when considering either a GT major or a flexibility upgrade to make sure potential constraints are addressed in the most cost effective way possible. The session continued with an overview of GT and Plant fast start offerings as well as an update on important Steam Turbine and Generator TILs. As we closed with the usual Q&A session, Users' questions was addressed and the dialogue will continue in the User Conference in november 2022. Also decarbonization as a broad subject will be fully covered in the November Users Conference. |

3rd Party Service Providers

|

|

FREUDENBERG New classification system simplifies filter selection Site- and plant-optimized solutions in intake air filtration offer operators of turbomachinery valuable potential for optimization in terms of performance, operational reliability and ease of maintenance. Up to now, the available test standards ISO 16890 (formerly also EN 779) and ISO 29463 / EN 1822 have only been of limited help when it comes to meaningful evaluation and needs-based selection of intake air filters for rotary machines such as gas turbines and compressors. The reason is that they were designed for filters used in general ventilation and airconditioning systems. This has changed when mid-September 2021 the Part 1 of the revised ISO 29461 has come into force. It specifies how the corresponding performance parameters of static air filters used in such systems are determined and classified. The 13 filter classes of the ISO 29461-1 standard create transparency, allowing filter performance to be objectively compared. The volume flow rates and final pressure drops used to determine dustholding capacity have been adapted to the realities of turbomachinery. The new standard now also describes the procedure for determining the dust-holding capacity of EPA and HEPA filters, which was previously not covered by the ISO 29463 and EN 1822 standards. In addition, ISO 29461-1 for the first time provides concrete installation specifications for testing round filter elements, i.e. filter cartridges. Classification according to T classes More information about the new standard is available at www.iso29461-1.com. As well as an explanatory video interview with Dr. Caesar, visitors can watch the online filter class configurator according to ISO 29461-1 and can download a detailed customer information with comparison tables. The industry specific e.FFECT brochure can be download here.

|

|

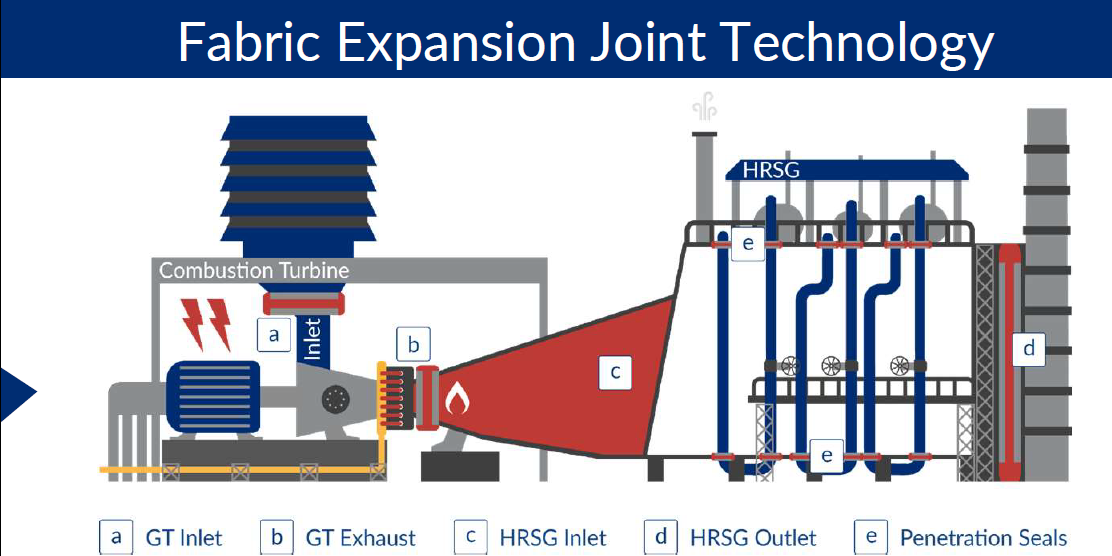

DEKOMTE manufactures fabric and metallic expansion joints and bellows, designed and constructed to compensate for changes in length due to shifting temperatures in duct work. Axial, lateral and angular movements are compensated for. DEKOMTE expansion joints are available in any geometric shape (round, square, oval, multi-sided) and in any size. Dekomte presented on it’s experience of supplying for the GT26 fleet, with 3 topics;

|

|

|

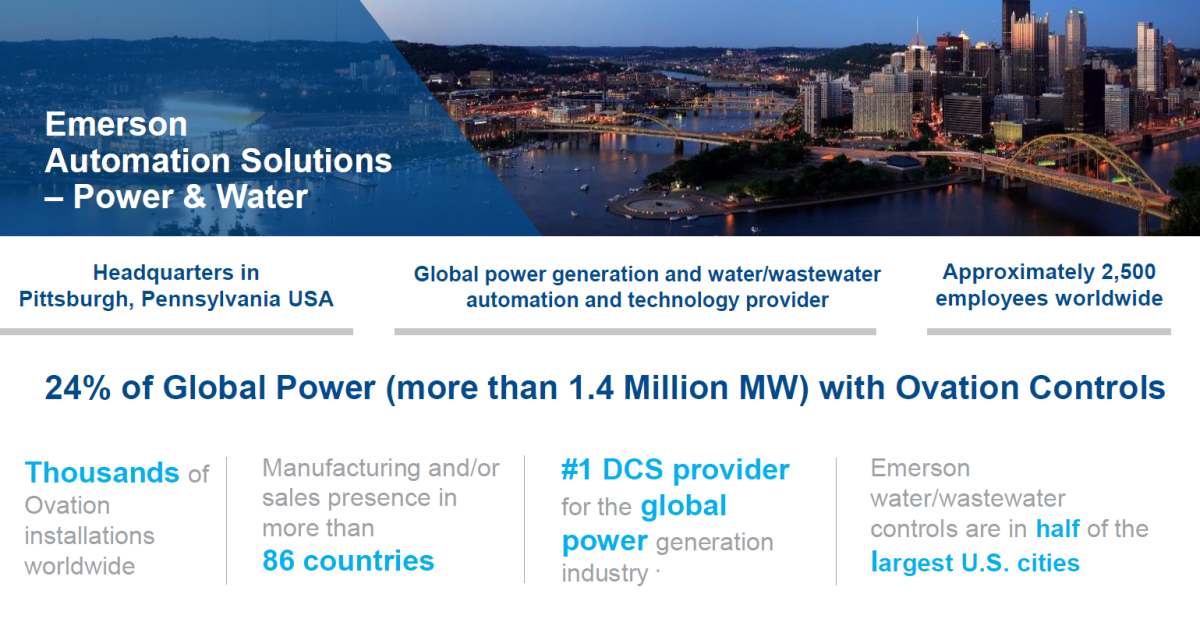

Emerson Controls – One Ovation™ Platform for Fully Integrated Gas Turbine and Combined Cycle Plant Control The session began with Yasin providing an overview of Emer-son’s extensive industry experience of automating 1.4 million megawatts of global power generation. Our project implementation organization includes a dedicated team of experts who have installed gas and steam turbine solutions worldwide for every major OEM and turbine model. Specialists at our gas turbine center focus on developing and testing core logic, advanced control functions, control enhancements and gas turbine simulation models. Laurence introduced Ansaldo Energia’s selection of Emerson’s Ovation™ automation technology as the OEM control system for the GT26 and GT36 new build models in addition to our retrofit capabilities for the GT26 gas turbine. A single Ovation platform provides complete, integrated control of all turbine and plant functions, all supported by comprehensive lifecycle services and cybersecurity solutions. The use of a common platform increases operational visibility, reliability and availability while reducing O&M costs. Emerson’s upgrade solution for GT26 turbines and combined cycle power plants was discussed as well as a matrix that depicts how each component of the ABB Advant and Alstom Alspa5 and Alspa6 systems can be upgraded to an integrated Ovation system. Yasin provided details on Emerson’s Alspa6 GT26 control panel upgrade solution and Laurence described a case study where Emerson upgraded a large 2-on-1 combined cycle plant equipped with Alstom GT13E2 gas turbines. The project scope included replacing the Advant gas turbine and Alspa5 plant and steam turbine controls with an Ovation solution that included integrated excitation controls, condition monitoring, SIL3 safety systems, high-speed data recording and a simulator.

For more information, please visit our gas turbine controls website or contact yasin.demir@emerson.com or laurence.otoole@emerson.com.

|